Uğur: a Global Pioneer

in Cooling Solutions

With over 250,000 m² of production space, 2,500+ employees, and 1.2 million coolers manufactured

each year, Uğur is one of the most respected names

in refrigeration.

Its solutions support iconic global brands

including Unilever, Danone, Nestlé, Pepsi, Coca Cola, Heineken, Red Bull, and many more.

But leadership also means anticipating change.

And Europe’s evolving energy efficiency regulation -combined with beverage brands’ commitment

to sustainability - were clear signals:

by 2027, only Class A commercial coolers will meet market expectations.

So Uğur decided to start the transition now.

The Challenge:

Reimagining Efficiency

Upgrading a commercial cooler from Class B to Class A is no simple task.

It requires rethinking insulation, hardware, and—most importantly—the intelligence behind the system.

Together, Uğur and Eliwell explored multiple avenues: new door technologies,

high efficiency compressors, and advanced electronics.

The choice became clear: unlock the full potential of variable

speed refrigeration through an innovative control strategy.

This is where the partnership flourished.

A Collaboration Built on Shared Expertise

Eliwell and Uğur engineers worked side by side, running hundreds of hours

of lab tests under challenging conditions - 25°C with 80% humidity - where

each cooler had to reach the target temperature within 13 hours.

“We combined our control electronics expertise with Uğur’s

deep application knowledge. Together, we developed optimized

algorithms for our EWNext platform, testing multiple approaches

until we found the one that delivered the breakthrough,”

says Michele Dal Molin, Senior Business Development Manager, Sales for Eliwell.

The result?

A new way of controlling the cooler:

precise, responsive, and remarkably efficient.

The Breakthrough:

Eliwell EWNext 978 P/BI

At the core of the upgrade is the Eliwell EWNext 978 P/BI, a custom controller for Uğur’s beverage coolers.

Its strengths include:

- A highly flexible parameter architecture for fine-tuned adaptation

- Advanced variable speed compressor management

- Optimized control of fans and defrost cycles

- Dynamic modulation of refrigeration capacity

It continuously matches power to real cooling demand, improving efficiency and performance, and responds quickly during recovery and peak loads thanks to energy-saving parameters and VSC management. The decisive factor, beyond the technology, was the close engineering collaboration that refined algorithms and parameters to the best result.

How Uğur Engineered the Leap to A‑Class Energy Performance

Uğur Cooling achieved A energy class performance in one of its cabinet models using an advanced thermostat controller. This result came not just from component selection, but from a structured engineering process backed by extensive validation tests, fully compliant with standards and conducted under simulated real field conditions. The EWNext978 operating principle was analyzed to define capabilities and limits, its functional potential was assessed, and application-specific requirements were set. Energy efficiency and real-world performance were addressed together through a detailed control strategy. After this groundwork, Uğur and Eliwell teams collaborated through structured meetings and iterative testing to translate requirements into measurable targets and optimize parameters in realistic operating scenarios—improving efficiency without compromising performance.

“The attainment of A energy class stands as a result of data-driven validation, precise control strategy development, and strong cross-functional collaboration between UGUR and Eliwell. The project demonstrates how electronic control thermostats, when properly understood and jointly developed, can become a strategic lever for sustainable efficiency gains.’’

MR Bora DEVRIM, Uğur COO

The Results:

A Giant Leap Forward

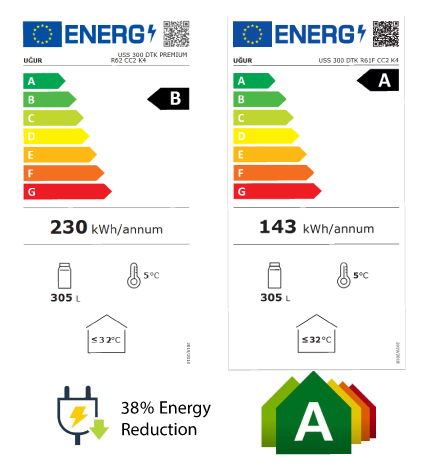

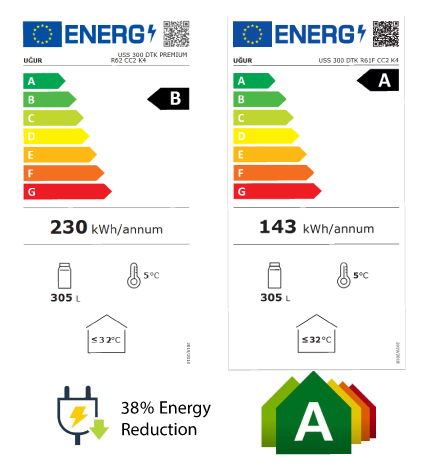

The upgraded Uğur coolers have achieved:

This achievement positions Uğur among the first manufacturers

worldwide to offer 300- and 400-liter beverage coolers in Energy Class A.

And the collaboration is far from over:

Eliwell and Uğur are already working on efficiency upgrades

for larger plug in commercial coolers, expanding the impact of the solution.

energy reduction for 300lt models

energy reduction for 450lt models

Beyond Energy Savings:

A Competitive Advantage

Energy efficiency is more than a performance metric: it’s an economic

and environmental opportunity.

To illustrate the impact, consider a mid-sized city like Venice,

with an estimated 2,000 commercial coolers.

If only half of them were replaced

with Uğur’s Class A models:

- consumption would drop from 600 kWh/year to 143 kWh/year per cooler

- total savings would reach 457,000 kWh/year

- equivalent to over €130,000 saved annually

- equal to the energy consumption of 169 households

- and a reduction of more than 150,000 kg of CO₂ each year

A compelling case where sustainability meets real world business value

A Shared Vision for the Future

Eliwell’s Next platform continues to evolve.

In late 2025, the company introduced EWNext 1000, a new generation

of advanced controllers designed for high efficiency refrigeration systems,

with cutting edge modulation, humidity control, scalability, and connectivity.

Uğur is now evaluating the adoption of this new platform to upgrade larger

and more sophisticated coolers to Class A.

The journey toward sustainable refrigeration continues:

Uğur and Eliwell are shaping it together.